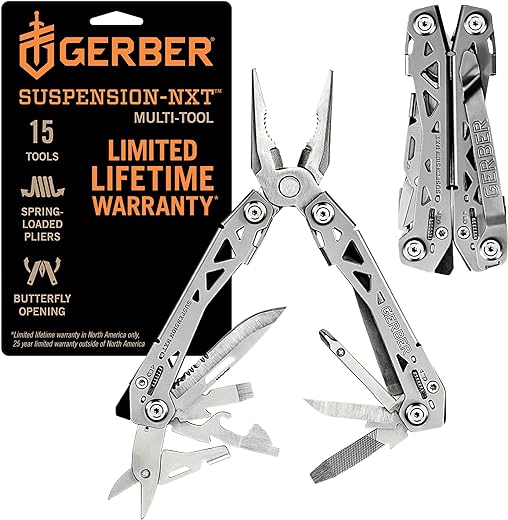

In this step-by-step guide, you’ll find expert tips on how to repair a travel-sized multi-tool. Whether it’s a loose screw, a broken blade, or a malfunctioning tool, this guide has got you covered. With easy-to-follow instructions, you’ll be able to troubleshoot and fix common issues with your multi-tool, ensuring that it’s ready for your next adventure. Get ready to become your own handyman and keep your multi-tool in top shape!

Compact and versatile must-haves for travelers

Gather the necessary tools and materials

To ensure a smooth and efficient repair process for your travel-sized multi-tool, it is important to gather all the necessary tools and materials beforehand. Start by checking if you have any replacement parts that may be required for the repair. It’s always a good idea to have a small screwdriver set on hand, as this will come in handy for removing and tightening screws. Additionally, make sure you have some lubricant available to keep the mechanisms of your multi-tool functioning properly. Finally, don’t forget to grab a cleaning cloth to wipe away any dirt or debris that may have accumulated. By having all these items ready before you start, you’ll be well-prepared to tackle the repair and complete it efficiently.

Identify the problem

To identify the problem with your multi-tool, start by examining it closely. Look for any visible signs of damage or malfunction. Is there a loose screw that needs tightening? Is a blade broken or missing? Or maybe you’ve noticed that a particular mechanism is not working properly.

Once you have identified the specific issue, you can determine the appropriate solution and guide your repair efforts accordingly. If it’s a loose screw, use a screwdriver to tighten it securely. For a broken blade, you may need to replace it with a new one. And if you’re dealing with a malfunctioning mechanism, try troubleshooting or consulting the user manual for guidance on how to fix it.

Remember, understanding the problem is the first step towards fixing it. Take your time to thoroughly examine your multi-tool and determine the precise issue at hand. This will ensure that you take the right steps towards resolving the problem efficiently and effectively.

Disassemble the multi-tool

To carefully disassemble your travel-sized multi-tool, follow these easy steps:

- Gather the appropriate tools: You will need a small screwdriver set, pliers, and possibly a small hammer or mallet.

- Find the screws: Look for the small screws that hold the tool together. They are usually located on the handle or along the sides. Use the appropriate screwdriver to carefully remove these screws. Keep them in a safe place.

- Separate the components: Once the screws are removed, gently pry apart the different parts of the multi-tool. Be cautious not to force anything or use excessive pressure, as this could damage the tool.

- Observe how the components fit together: As you disassemble the multi-tool, pay attention to the order and orientation of each component. Take note of any specific steps or details required for reassembly. This will ensure that you can put everything back together correctly later.

- Take pictures or make diagrams: If you’re worried about forgetting any details during the repair process, it can be helpful to take pictures or make diagrams of the disassembled multi-tool. This will serve as a visual reference when it comes time to reassemble the tool.

Remember, disassembling a multi-tool can be a complex task, so take your time and proceed with caution. By following these steps and paying attention to the details, you’ll be well-prepared to repair and reassemble your multi-tool successfully.

Clean and lubricate the parts

- Clean all the components of your multi-tool using a mild detergent and a soft cleaning cloth. Gently scrub each part to remove any dirt, debris, or rust that may have accumulated over time. Ensure that you reach all the nooks and crannies to achieve a thorough cleaning.

- Rinse the components with clean water to remove any detergent residue. Make sure to dry them completely using a clean cloth or allow them to air-dry naturally. This step is crucial to prevent any moisture from causing corrosion or damage to the parts.

- Apply lubricant to the moving parts of your multi-tool. Use a designated lubricant that is suitable for the specific type of mechanism and material of your tool. Apply a small amount of lubricant to each moving part, focusing on joints, hinges, and pivot points. This will ensure smooth functionality and prevent friction-related issues.

- Wipe off any excess lubricant to avoid attracting dirt and dust. Use a clean cloth to gently wipe away any surplus lubricant from the surfaces of the components. Be thorough but careful not to remove all the lubricant, as a thin layer is necessary to maintain optimal performance.

By following these simple steps, you can effectively clean and lubricate the parts of your multi-tool, ensuring its longevity and reliable performance in your future endeavors.

Replace or repair damaged parts

If you have identified any damaged or broken parts, take action now to replace or repair them. Follow these simple steps to ensure a smooth process:

- Consult the manufacturer’s instructions: Start by checking the user manual or any documentation provided by the manufacturer. They might have specific guidelines on replacing or repairing damaged parts. If you don’t have the manual, try looking it up online or contacting the manufacturer directly.

- Seek professional advice if necessary: If you’re unsure about tackling the replacement or repair yourself, it’s always a good idea to consult a professional. They can provide expert guidance and ensure the job is done correctly.

- Gather the appropriate tools and materials: Before you begin, make sure you have all the necessary tools and materials. This might include screwdrivers, wrenches, replacement parts, adhesive, or any other specific items mentioned in the manufacturer’s instructions.

- Carefully remove the damaged part: Follow the manufacturer’s instructions to safely remove the damaged part. Be gentle and take your time to avoid causing any further damage.

- Replace or repair the part: Depending on the extent of the damage, you may need to either replace the part entirely or repair it. Follow the manufacturer’s instructions or seek guidance from a professional to ensure you use the correct techniques and materials.

- Ensure a proper fit: When replacing the part, ensure it fits snugly and securely. Double-check that any screws or fasteners are tightened properly, but be careful not to overtighten and risk damaging the part.

- Test for functionality: Once the replacement or repair is complete, test the functionality of the repaired item. Make sure it operates as expected and that any issues or malfunctions have been resolved.

Remember, if in doubt, it’s always better to seek professional assistance to avoid causing further damage or voiding any warranties.

Reassemble the multi-tool

To reassemble your travel-sized multi-tool, follow the reverse order of disassembly. Start by referring to your notes, pictures, or diagrams to ensure you put everything back together correctly. Take your time and double-check each step to avoid any mistakes.

Begin by carefully attaching the various components of the multi-tool, such as the blades, pliers, and screwdriver heads, back onto the main body. Make sure each piece is securely fastened and aligned properly. Next, reattach any additional features, such as the can opener or file, according to their designated positions.

Once all the components are in place, carefully tighten any screws or bolts that were removed during the disassembly process. Ensure that each fastening is secure but be cautious not to overtighten, as this may damage the tool.

Finally, give your reassembled multi-tool a thorough inspection to ensure everything is in proper working order. Test each feature to ensure they function as intended. If you notice any issues or if something doesn’t seem right, retrace your steps and make any necessary adjustments.

Remember, reassembling your multi-tool requires patience and attention to detail. By following these steps and referring to your documentation, you can confidently put your multi-tool back together correctly and have it ready for your next adventure.

Test and fine-tune the repaired multi-tool

Once you have successfully reassembled your multi-tool, it’s important to thoroughly test its functionality to ensure everything is working as intended. Follow the steps below to perform a comprehensive test and make any necessary adjustments for optimal performance:

- Check for proper functionality: Test each individual component of the multi-tool to ensure they are operating correctly. This includes checking the blades, pliers, screwdrivers, and any other tools included in your multi-tool. Make sure they open and close smoothly, without any stiffness or resistance.

- Inspect for any lingering issues: Pay close attention to any issues or problems you had identified earlier during the repair process. Verify whether these issues have been resolved or if they still persist. Take note of any parts that require further attention.

- Adjust and fine-tune: If you encounter any problems during the testing phase, it’s time to make the necessary adjustments for optimal performance. Here are a few key areas to focus on:

- Tightening screws and bolts: Ensure that all screws and bolts are tightened securely, but be careful not to overtighten them, as this may cause damage.

- Lubrication: Apply a small amount of lubricant to the moving parts of your multi-tool to reduce friction and enhance performance. This is particularly important for hinges, pivots, and other areas that require smooth movement.

- Alignment: Check the alignment of the various components and adjust as needed. Sometimes, parts can shift during the repair process, leading to misalignment and decreased functionality.

- Re-test and evaluate: After making the necessary adjustments, retest your multi-tool to verify that all issues have been resolved. Repeat the tests you performed earlier to ensure proper functionality. If everything is working smoothly, congratulations! Your repaired multi-tool is ready for action.

Remember, the key to successfully testing and fine-tuning your repaired multi-tool is to be thorough and pay attention to detail. By following these steps, you can ensure that your multi-tool is in top-notch condition and ready to assist you with your various tasks.

Wrapping up the repair process

In conclusion, repairing a travel-sized multi-tool doesn’t have to be a daunting task. With the guidance provided in this blog post, you now have the necessary skills to fix common issues that may arise. Just remember to prioritize safety and seek professional help or refer to manufacturer guidelines when necessary. By properly maintaining and repairing your multi-tool, you can ensure its longevity and continue to rely on its versatility and convenience for all your future adventures. Happy repairing!

When cleaning the parts, I recommend using a mild solvent or degreaser to remove any built-up dirt or grime. It can make a big difference in the performance of the multi-tool.

Thanks for the suggestion! Using a mild solvent or degreaser is a great way to ensure the parts are thoroughly cleaned.

That’s a great tip! Using a magnetic tray is a smart way to keep track of the screws and small parts.

I think it would be helpful to include some troubleshooting tips in case someone encounters difficulties during the repair process. For example, what should we do if we can’t remove a stuck screw?

That’s a valid point. I’ll make sure to update the guide with some troubleshooting tips, including how to deal with stuck screws. Thank you for the feedback!

One additional tip I have is to take pictures or make a diagram while disassembling the multi-tool. This can be useful when reassembling to ensure everything is put back correctly.

That’s a great suggestion! Taking pictures or making a diagram can definitely help with reassembly. It’s always good to have a visual reference.

I found that using a small magnetic tray to hold the screws and small parts during disassembly was really helpful. It prevented me from losing any pieces.

I followed this guide and was able to successfully repair my travel-sized multi-tool. The problem was a loose screw that was causing the tool to malfunction. Thanks for the clear instructions!

I’m glad to hear that the guide helped you repair your multi-tool! It’s always satisfying to fix something yourself. Well done!